WELD INSPECTION ETCHANTS

Our macro-etching acids are expertly formulated by metallurgists to reveal the weld nugget during the weld penetration test. These chemicals are effective on stainless steel, mild steel, aluminum, and more. They come pre-mixed, ready-to-use, and can be stored at room temperature for up to a year.

A typical macroetching procedure for weldments usually starts with cut mark removal using a series of sandpapers, progressing from coarse to fine. We wet sand the surface using 180 grit, 320 grit, and 600 grit sandpapers. The cross-sectional surface should have a uniform 600 grit finish, at a minimum, before proceeding to the next step. Mirror-polish the surface if possible. The finer the finish, the better the etching chemical will work, revealing more details. After preparing the surface, rinse and dry it, then apply the etchant with cotton swabs. Allow it to stand for a few seconds to minutes. Once the weld is visible, rinse it with water to stop the reaction.

If you require assistance with a special weldment, please send a small sample to us. We will recommend a suitable product based on the test results.

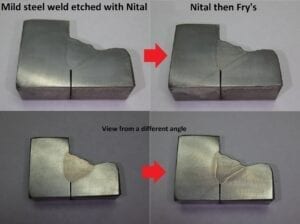

Carbon Steel Welds:

- Nital Etch, 5%: The traditional choice for carbon steel welds. AKA Nitol or Nytal. It contains nitric acid and is more effective than rust removal jelly.

- Fry’s Reagent: (Optional 2nd stage) For highlighting mild steel welds. Fry’s is used after Nital etching. It will stain the weld nugget making it darker and easier to see.

Picture: A36 mild steel weld

Stainless Steel Welds:

- Stainless Steel Weld Etch: Our general-purpose stainless steel etchant. Unlike Lepito’s Etch or Aqua Regia, no mixing or heating is required. It can also be stored at room temperature for up to a year.

Pictures: 304, 308, 316, 409, 439, 2205 duplex, 17-7 PH welds

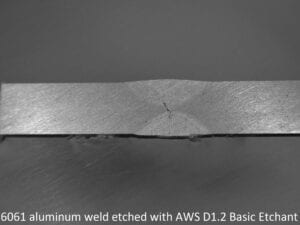

Aluminum Welds:

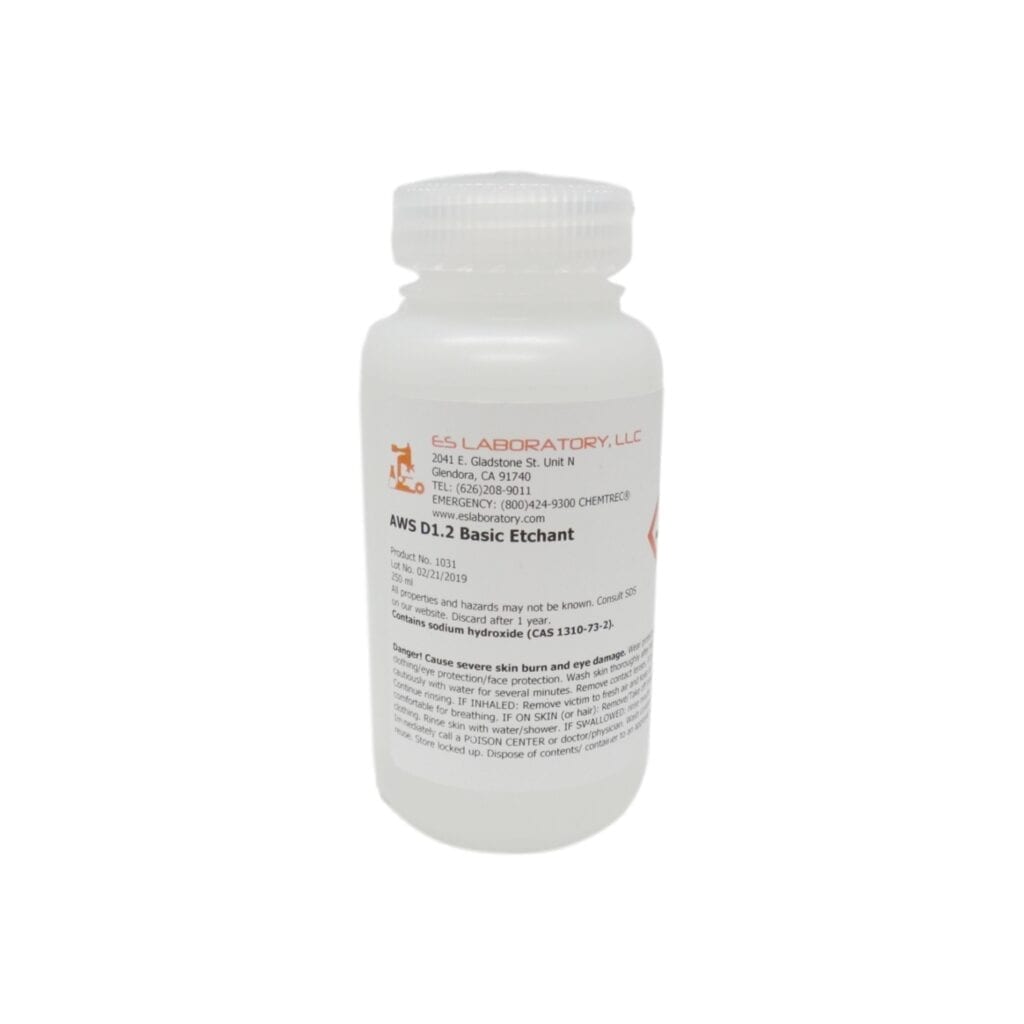

- AWS D1.2 Basic Etchant: Listed in welding code D1.2. Fast and effective.

Pictures: 3003, 5052, 5085, 5456, 6061, 6063 welds

- Keller’s Reagent: For advanced users only. It contains hydrofluoric acid! Please handle it with care.

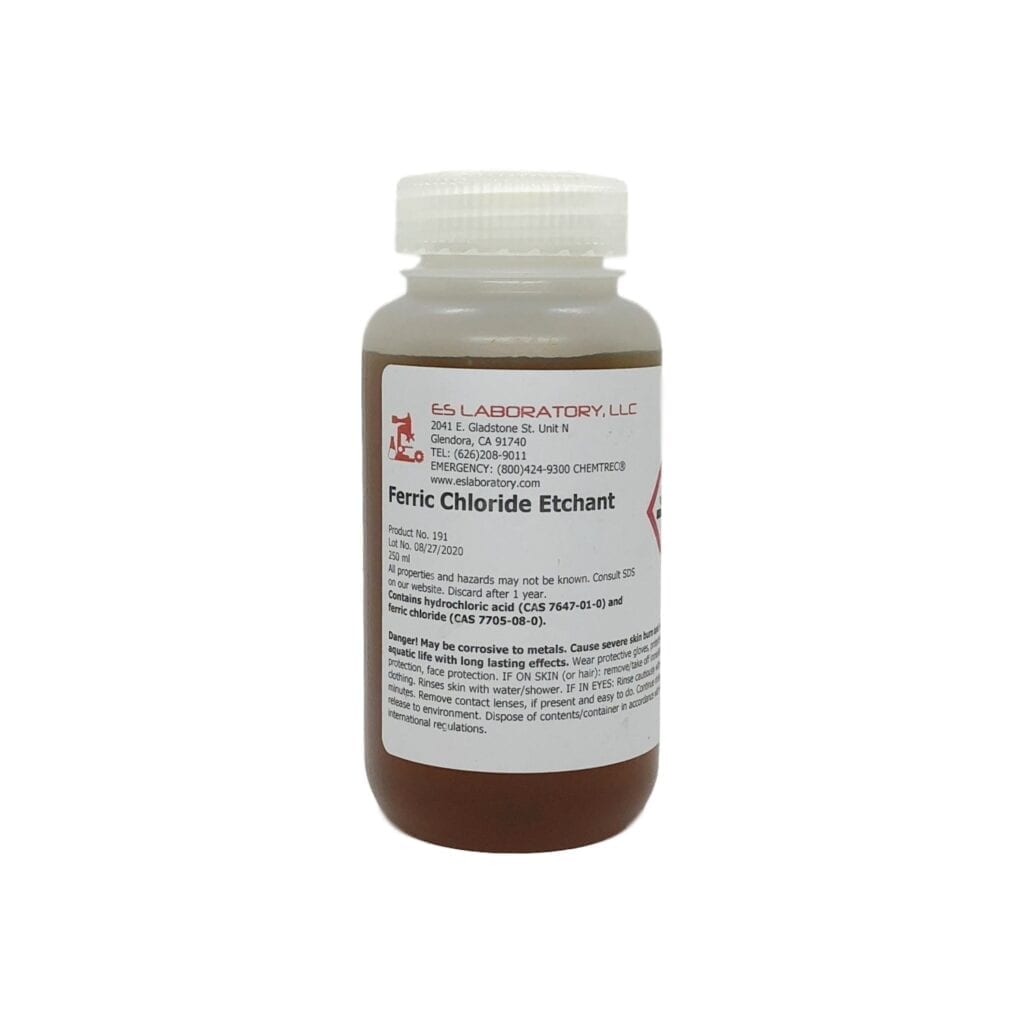

Copper & Brass Welds:

- Ferric Chloride Etchant: General-purpose etch for copper-based welds. Pre-mixed, ready to use.

Titanium Welds:

- AWS D1.9 Titanium Weld Etch: Listed in welding code D1.9. It contains hydrofluoric acid! Please handle it with care.

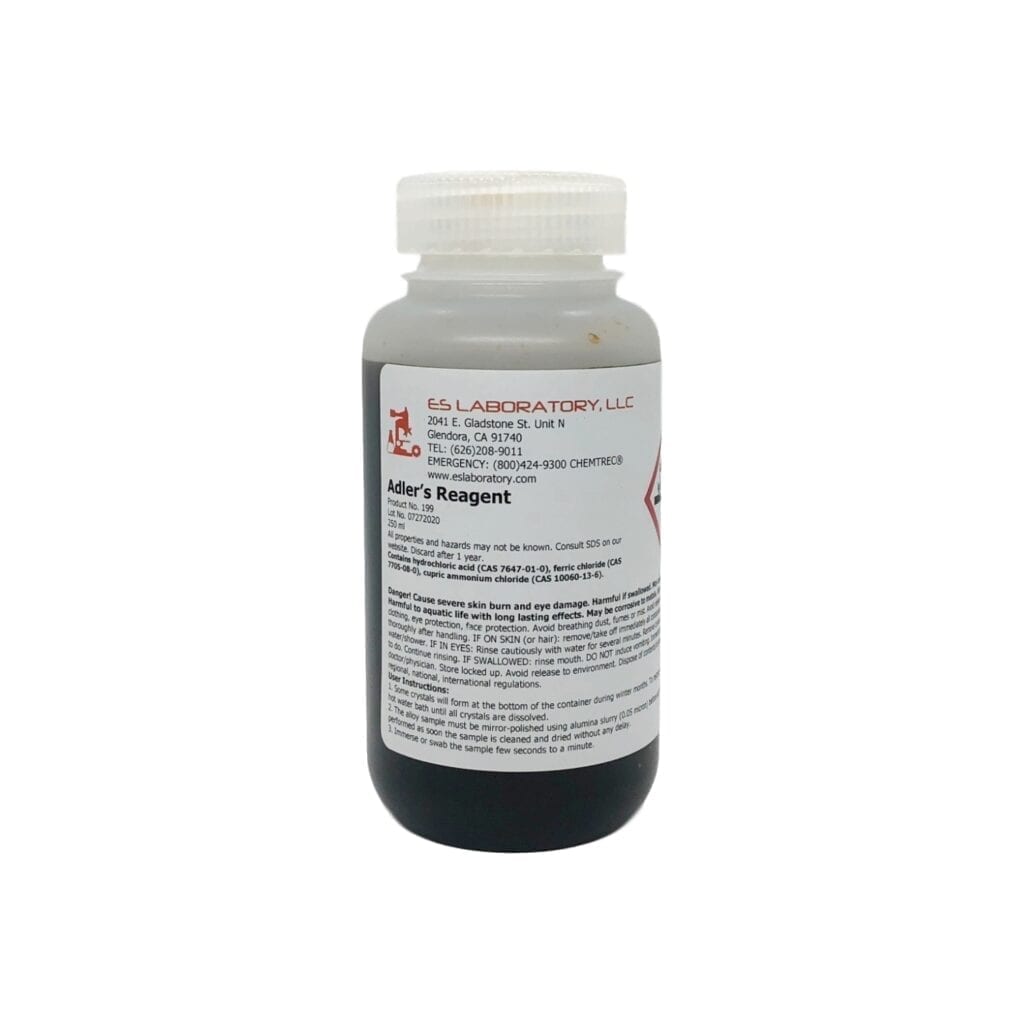

Inconel 625 Weld:

- Sand the weld surface to a uniform 600 grit finish. Rinse and dry the surface quickly, then etch it immediately with our Adler’s Reagent without any delay. Otherwise, Inco 625 will react with air and passivate.

Picture: Inco 625 weld

These chemicals are also available in the 500 ml size, see below.

-

Now serving US & Canada.🇺🇸🇨🇦

-

All prices are in $USD.

-

Overnight and UPS collect available.

-

Commercial shipping address required.