PRE-PENETRANT ETCHANTS

These pre-penetrant etch formulas were developed by jet engine companies for NDT inspection of different metals. They will remove smeared metal from the surface, reveal hairline cracks, and prepare the part for the subsequent fluorescent penetrant inspection (FPI).

Etchants from GE, Honeywell, and P&W specifications:

- Class A, for magnesium alloys

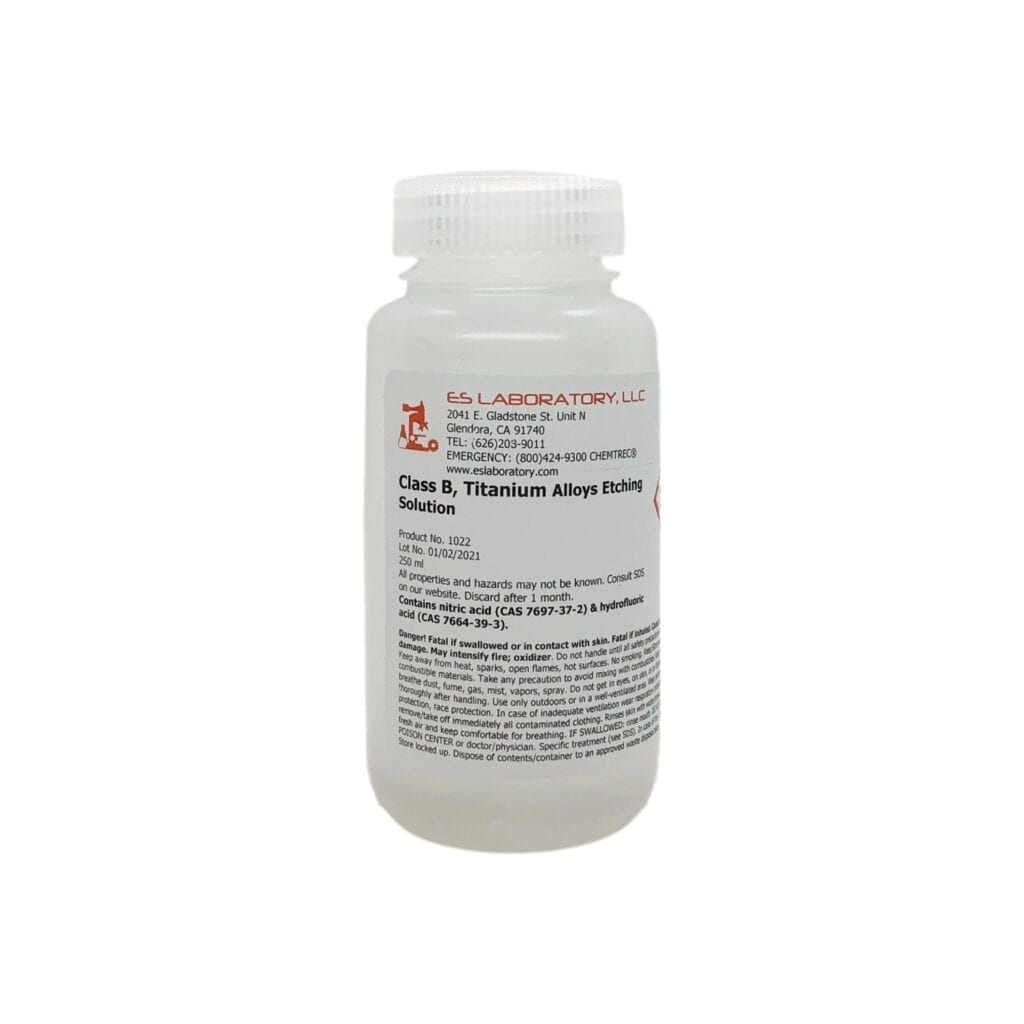

- Class B, for titanium alloys

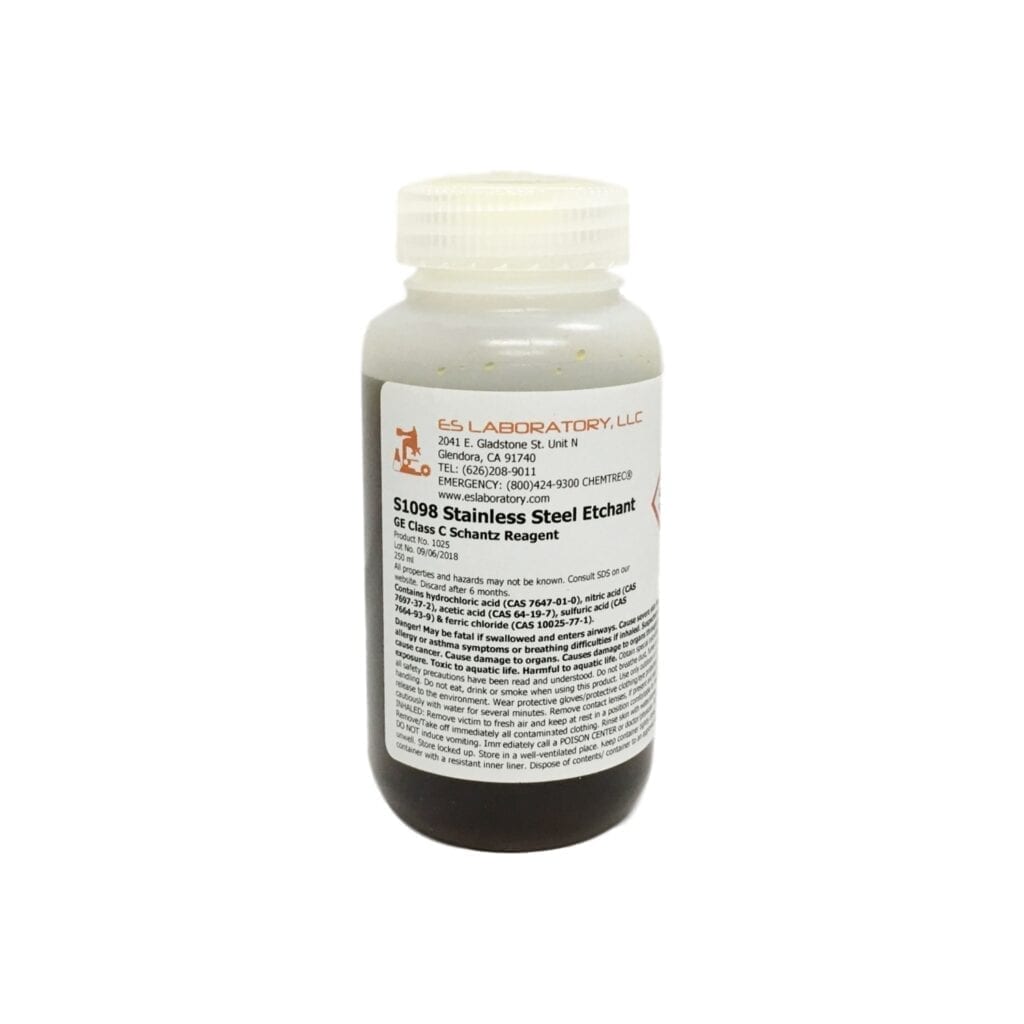

- Class C “Schantz reagent”, for stainless steel and alloys listed below:

- 300- and 400-series stainless steels, precipitation hardening steels, A-286, maraging steels, Rene’ 77, Rene’ 80, Rene’ 95, Rene’ 100, Rene’ 125, Udiment 500, Sel, Sel 15, TD-NiCr, Waspalloy, 17-4 PH, Hastelloy B, C, and W.

- Class E, for carbon steels

- Class F, for aluminum alloys

- Class G, for Inconel-718

Etchants from CFM specifications:

- S1093 titanium alloy etchant

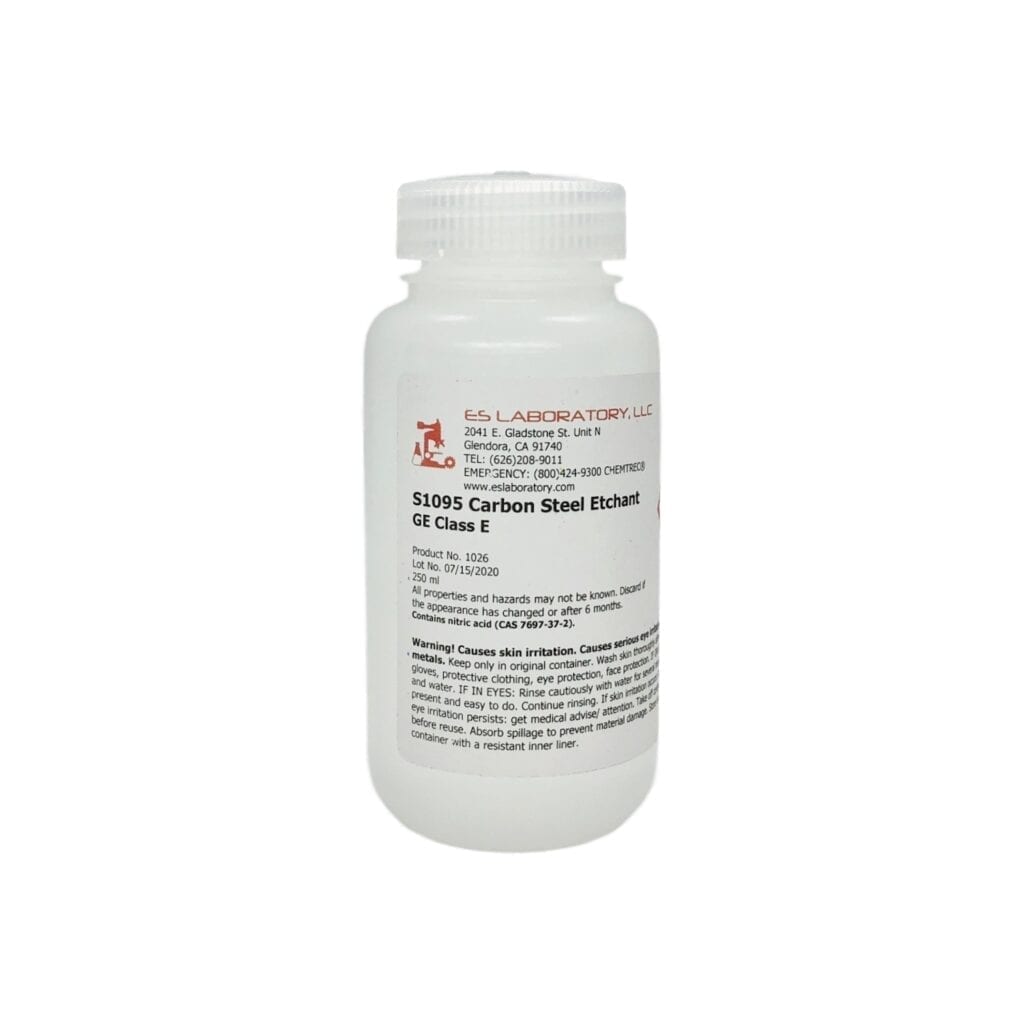

- S1095 carbon steel etchant (equivalent to Class E)

- S1096 aluminum alloys etchant

- S1098 stainless steel etchant (equivalent to Class C)

Others:

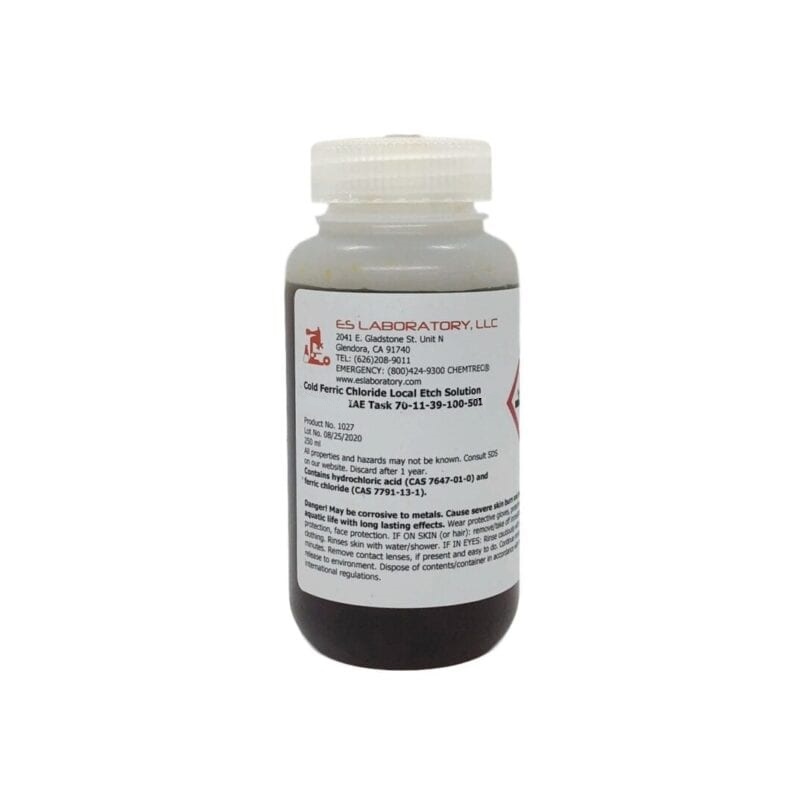

- Cold ferric chloride local etch solution, IAE Task 70-11-39-100-501

- Aluminum etching gel

- A pre-penetrant etchant for Al alloys that has a gel consistency, tailored to prevent running on non-flat surfaces during application.

Note: These chemicals are professional products, we will not provide the testing procedure. Please contact the engine manufacturer for the NDT test manual.

-

Now serving US & Canada.🇺🇸🇨🇦

-

All prices are in $USD.

-

Overnight and UPS collect available.

-

Commercial shipping address required.